service

Pumping stations are the unsung heroes of modern infrastructure, silently driving the flow of water and wastewater across cities, industries, and facilities. From transporting stormwater and sewage through pumping stations to maintaining water supply for firefighting and irrigation, these systems ensure fluid movement where gravity alone isn’t enough.

At Middle East Group, we specialize in the complete MEP scope of sewage and wastewater pumping stations—delivering seamless mechanical, electrical, and instrumentation works tailored for smooth, efficient operation. From pump and equipment installation and piping to cabling, control panels, and automation systems, our team ensures every component performs with reliability and precision. We bring years of hands-on expertise as an MEP contractor for pumping station works, executing projects to the highest standards in compliance with local authority regulations and project specifications.

Customized automation systems for smart manufacturing in various sectors.

Our services span the complete MEP spectrum – plumbing, electrical, and mechanical, for wastewater and sewage pumping station projects. We ensure that each component is engineered, installed, and integrated to deliver optimum reliability, operational efficiency, and long-term performance under demanding site and field conditions.

Middle East Group has handled an innumerable variety of sewage and wastewater pumping station projects with distinct operational requirements. Every station is engineered to suit particular flow rates, fluid types, and head pressures while making it sure that compliance is adherent to local authority standards and operational norms or guidelines.

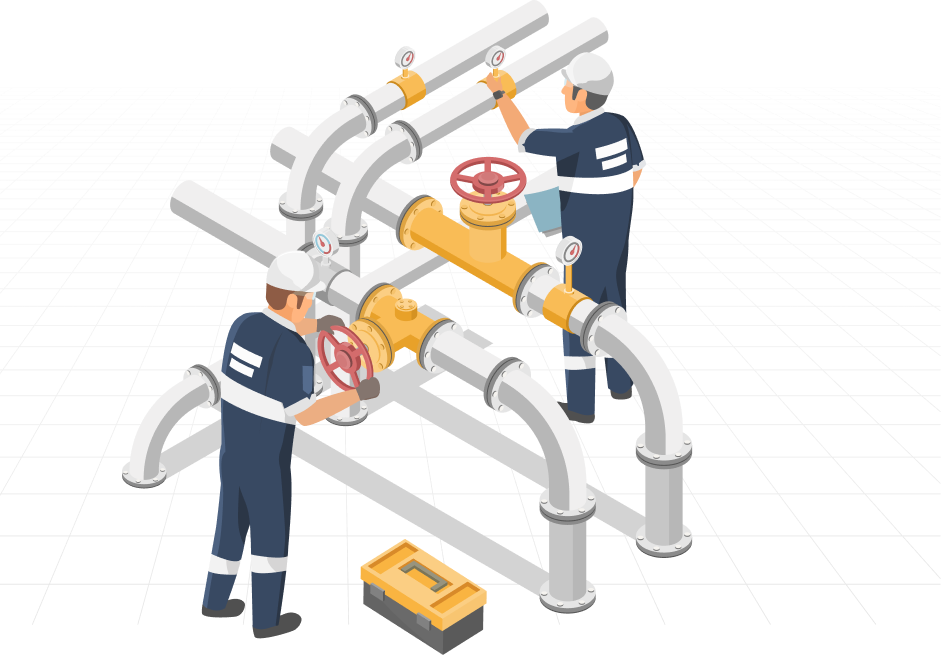

Our mechanical works span across the supply, assembly, and alignment of core sewage and wastewater pumping station components. Whether you have a small residential unit or a high-capacity municipal station, we provide accurate and efficient mechanical installations.

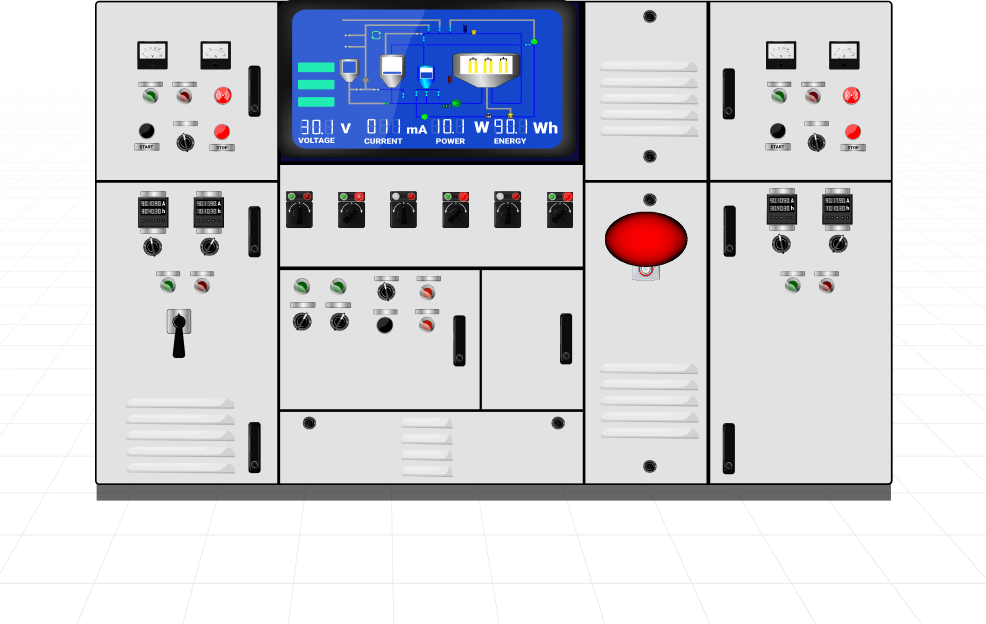

Electrical design and installation are the backbone of any pumping station functionality. We deploy LV/MV switchgear, Smart power and advances control systems to ensure that operations are safer and remotely monitored as and when needed. We provide latest remote monitoring and SCADA integration technologies to ensure the connectivity between local stations and central control rooms. We always make sure our system is energy efficient and can perform at its best efficiency all time.

Before handing over, each sewage and wastewater pumping station is vigorously tested to make sure that it meets all performance benchmarks and standards. We execute hydraulic testing and flow validation along with safety checks and complete documentation for authority approval. This all ensures long-term operations without any hassle.

Middle East Group Holding LLC is highly renowned for its sewage and wastewater pumping station engineering services. We have successfully delivered ample pumping station projects across and beyond the region. We have earned the trust of municipalities, developers, and consultants alike. We have in-house MEP teams to ensure seamless collaboration, flawless execution, and stringent compliance with international standards and norms for pumping station works.

Customized automation systems for smart manufacturing in various sectors.

efficient water management systems, we are committed to addressing the world’s most critical water challenges. Our blog serves as a platform to share expert insights, breakthrough