Treated Sewage Effluent (TSE) is wastewater that has already undergone primary and secondary treatment at sewage treatment plants. While secondary treated water meets basic discharge standards, it often requires additional refinement—known as polishing—before it can be safely reused for critical applications. This is where TSE water polishing systems play a vital role.

In water-scarce regions across the Middle East, the demand for sustainable and reliable water reuse solutions is growing. A TSE polishing plant enhances the quality of treated effluent by removing remaining suspended solids, organic matter, pathogens, and trace contaminants, making the water suitable for reuse in irrigation, cooling systems, industrial processes, and municipal projects.

Middle East Group delivers advanced TSE polishing plant solutions designed to meet regional regulations, operational demands, and long-term sustainability goals. With strong engineering expertise and practical field experience, Middle East Group supports clients in implementing dependable water reuse systems that reduce freshwater dependency and environmental impact.

A TSE polishing plant is an advanced water treatment system installed downstream of a sewage treatment plant to further improve the quality of secondary treated wastewater.

While secondary treatment removes most organic matter and solids, polished TSE undergoes additional filtration and disinfection processes to achieve higher clarity, lower turbidity, and reduced microbial content. This final polishing stage is essential for reuse applications where consistent and higher water quality is required.

In simple terms, TSE polishing bridges the gap between basic wastewater treatment and safe, regulated water reuse.

TSE water polishing systems are critical for both regulatory compliance and operational reliability. Key benefits include:

TSE polishing plants are widely used across multiple sectors, including:

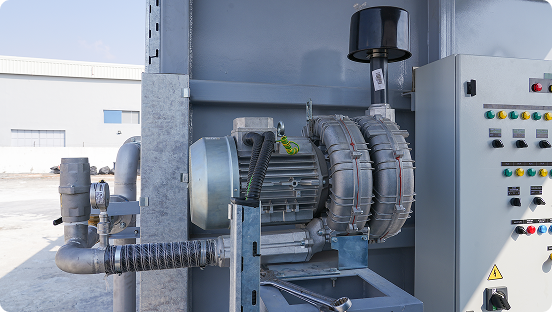

Modern TSE water polishing systems typically combine multiple treatment technologies to achieve consistent output quality:

Middle East Group designs and delivers TSE polishing plants with a focus on performance, reliability, and lifecycle efficiency:

Partnering with Middle East Group offers clear technical and commercial advantages:

TSE polishing plants support sustainable water management by:

Meeting local environmental and reuse regulations

Reducing freshwater extraction and consumption

Minimizing wastewater discharge into the environment

Supporting green building and sustainability initiatives

A TSE polishing plant is required by organizations that need reliable, regulation-compliant water reuse while reducing dependence on freshwater sources.

For safe reuse of treated wastewater in landscaping, district cooling, and non-potable public applications.

To meet environmental approvals, project specifications, and long-term water sustainability requirements.

For consistent-quality water used in cooling systems, utilities, and non-critical process applications.

To support HVAC make-up water, landscaping, and operational services with a controlled reuse water source.

For the irrigation of parks, golf courses, and large communities without impacting soil or plant health.